Mobile concrete batching plant YHZS75, whose production capacity is 75m³/h, adopts non-foundation and non-commissioning modular design, it features for good mobility, convenient and quick installation.

It only takes 3 days from installing to using. In addition to that, YHZS75 cement mixing plant adopts patent technology “click to supplement”, double control system, self-correcting technology to ensure producing high-quality concrete. YHZS75 adopt JS1500 twin-shaft compulsory mixer ad the host mixer, the mixing efficiency, mixing range wide, can fullest meet various producing requirement. YHZS75 batching plant is ideal concrete equipment for bridges, highway, port, water conservancy project and power station and so on.

Features

1.HZS60 concrete batching plant, whose production capacity is 75m3/h, flexibly consists of JS1500 twin shaft concrete mixer,

2.PLD2400 batching machine, cement silos, control system and relevant equipment.

3.can work independently. This kind of 75m3 concrete batch plant is of simple structure, easy installation and disassembling,

4.convenient construction, widely applied to various big and middle industry and civil construction of bridge,

5.highway, water conservancy project and wharf and so on. HZS75 cement batching plant, capable of excellent mixing hard-dry concrete,

6.light aggregate concrete and various mortars, is an ideal equipment to produce commercial concrete.

| Theoretical productivity of foundation-free HZS90 concrete mixing station | 75m3/h |

| concrete mixer model | JS1500 |

| Stirring motor power | 2×30kW |

| cycle period | 60/s |

| Mixer nominal capacity | 1500L |

| The largest particle size of aggregate | Φ80mm |

| Powder bin capacity | 50t/100t |

| Batching station batching capacity | 2400L |

| Aggregate bin capacity | 2×20m3 |

| Max.Dragging Speed | 40km/h |

| screw conveyor maximum productivity | 80t/h |

| Discharging height | 3.8m |

| Total Power | 100kw |

| Aggregate weighing range and accuracy | (0~5000)±2%kg |

| Cement weighing range and accuracy | (0~900)±1%kg |

| Fly ash weighing range and accuracy | (0~500)±1%kg |

| Water weighing range and accuracy | (0~400)±1%kg |

| Admixture weighing range and accuracy | (0~50)±1%kg |

Concrete mixer

YHZS75 concrete batch plant adopts top-quality JS1500 twin shaft forceful concrete mixer, which features for quick and uniform mixing, high efficiency, wide mixing range and excellent-quality concrete, can fullest meet different producing requirement.

PLD Series Batching Machine

PLD series concrete batching machine adopts electronic weighing, computer control and digital display, which can automatically complete the batching procedures of 3-6 kinds of aggregates such as sand, stone and cement. Hopper cumulative weighing, belt cumulative weighing and individual weighing are available.

Structure

Smart mobile concrete batching plant adopts strong and thick section steel, possessing good shock resistance ability, on the other hand, the overall structure is compact and well-designed, suitable for quick installation, dissembling and convenient dragging.

Cement Silo

It is suitable for bulk cement storage silos in engineering construction, commercial concrete mixing plant, road and bridge water conservancy projects, urban construction and other projects. It is waterproof, moisture-proof, prevents cement loss, reduces urban air dust pollution, has a small footprint, long service life, and low cost.

Weighing System

Water weighing, cement weighing, additive weighing, and other weighing systems can also be installed according to customer requirements. It adopts three-point weighing method, which has the characteristics of accurate weight, automatic compensation, fast speed and convenient operation. The weighing error is controlled within ±1%.

Control Room

The control system adopts Siemens hardware and Windows operating platform, which can realize manual operation, semi-automatic operation and fully automatic operation. Remote faults can be easily eliminated through the Internet and telecommunications, improving the user's ability to find problems and perform maintenance.

Control room

Full automatic control, Siemens motor and Schneider electrical elements. The controls system adopts Siemens hardware and Windows operation platform, can realize manual operation, semi-automatic operation and fully-automatic operation. Long-distance troubles can be excluded easily by internet and telecom, which largely improves users’ ability to find out the problems and carry on maintenance.

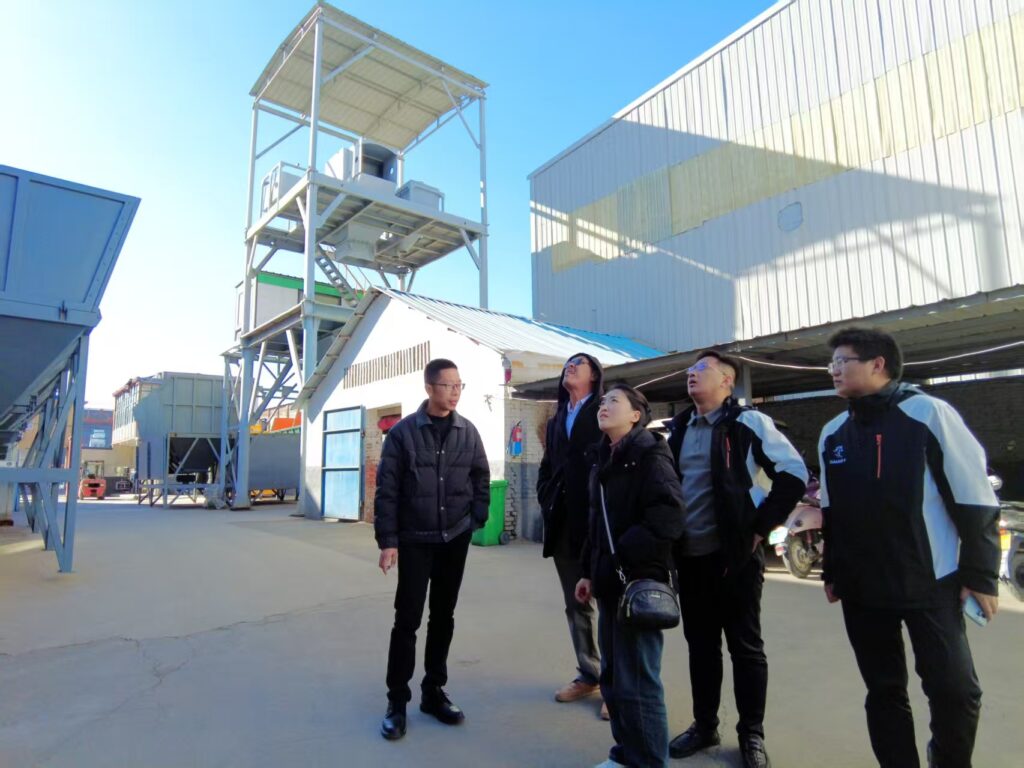

Zhengzhou Jinhuiyuan Machinery Manufacturing Co., Ltd. was established in 2000 and is located in Xingyang City, Henan Province, which is known as the "hometown of Chinese construction machinery". As a backbone enterprise in the construction machinery industry in Henan Province, the company has a registered capital of 31 million yuan and specializes in the research and development, manufacturing, and sales of engineering machinery and equipment such as concrete mixing plants and stabilized soil mixing plants. After more than 20 years of steady development, the company has grown into a modern mechanical manufacturing enterprise integrating research and development, production, sales, and service.

The company has always adhered to the development concept of "quality based enterprise, integrity management", and has obtained multiple authoritative certifications: ISO9001 international quality management system certification, environmental management system certification, occupational health and safety management system certification, and national AAA level quality service integrity unit.

With excellent product quality and a comprehensive service system, Jinhuiyuan Machinery's products are exported to more than 100 countries and regions around the world, including Asia Myanmar, Indonesia, Laos, Mongolia, Kazakhstan, Uzbekistan, etc; Europe Russia and surrounding regions; Africa - Angola, Zimbabwe, Algeria, etc. The company has established a global marketing network and set up offices and service outlets in key markets to ensure timely and professional service support for customers.

Jinhuiyuan Machinery always adheres to the service concept of "customer first" and has built a complete service system: 1 Pre sales service: Provide professional consultation and customized solution design In sales service: Arrange professional engineers to guide installation and debugging. 3 After sales service, the company has an experienced service team to ensure that global customers have no worries.

The company will continue to increase research and development investment, deepen international cooperation, and strive to become a globally competitive construction machinery manufacturing enterprise, contributing Chinese strength to the world's infrastructure construction.

1. Guarantee Time

All of the life time of SMART machine, free for the first 12 months except the wrong operation.

2. Free Spare Parts

SMART will prepare the one set spare parts and delivery them along with the machine.

SMART have the 12 workshops to produce every parts and we can produce spare parts to deliver them to you within 2 days.

3. Technical Supporting

SMART Engineer will train you workers to make sure that they know every detail about the machine to make sure they know how to deal with the urgent situation and can repair some normal problem.

4. Office

If we have more than 5 orders in one Area, we will set one office there to take care the after-sales service.

Please fill in the following form and leave your requirements, contact number, equipment usage location and other information, and describe the product requirements as detailed as possible. We will quickly process the information you submit and ensure that your purchase inquiry receives a timely and accurate response.